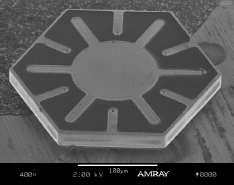

The big news out of Sandia National Laboratories today is micro solar cells — or “glitter-sized” as Sandia is calling them — that could halve the cost of solar panels while nearly doubling their efficiency.

Engineers have been working on Microsystems-Enabled Photovoltaics (MEPV) for some time, but the technology may have reached a tipping point, according to Sandia MEPV team leader, Greg Nielson.

“As the cells have matured and gotten to the point where we’re getting good, consistent performance, we’re ready to jump into making systems,” says Nielson. “We’ve got these cells; now what are we going to do with them?”

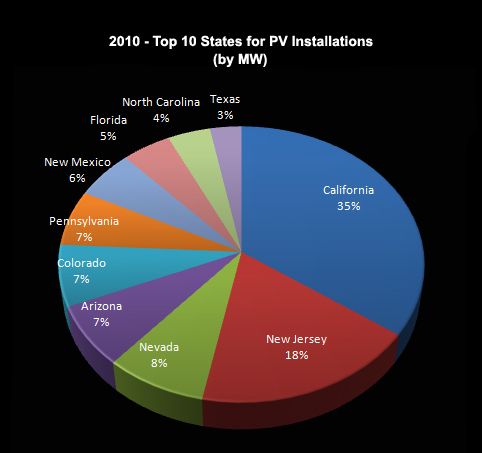

The answer: get them out of the lab and put them to work in the real world, thanks to an award by the Federal Laboratory Consortium. The technology transfer award allows Sandia to partner with private companies in five states, the National Renewable Energy Laboratory (NREL) in Golden, Colorado, and researchers at the University of South Florida. The team will adapt microfabrication technologies (already used in the semiconductor industry) to produce a new generation of crystalline silicon solar cells that could be as thin as 2-microns.

The diminutive cells are suspended in an ink-like solution and then printed onto an ultra-thin and low-cost substrate. The top layer of this “sandwich” is comprised of microlenses to focus the sun’s rays directly onto each solar cell.

Solar power has been taking a beating lately — unfairly, and politically motived, say supporters of renewable energy — because of the failure of the government-supported Solyndra company. But, as one solar-backer said, “for every failure there are dozens of new success stories that never get mentioned.”

Today’s announcement by Sandia is probably just the kind of story he had in mind.

There’s an excellent video illustrating the manufacturing process here. You can learn more about the technical details of MEPV development here and here.